Fabrication of metal-oxide films by spin-spray method

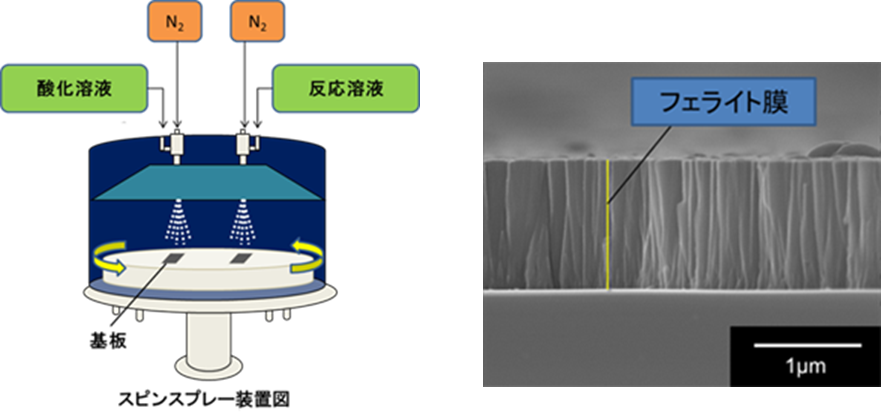

・ Spin-spray method

Spin-spray method is a thin film deposition technique by spraying solutions on a rotating heated stage. Source solution (containing metal ions) and reaction solution (containing oxidants or pH buffer) are sprayed from each nozzle by using N2 gas. Metal ions adsorb on hydrophilized substrate, then they are oxidized by oxidants and finally metal-oxide thin film is formed. The thin film deposition is completed below 100℃ and under ambient pressure, which is much easier than traditional sputtering method.

・ Ferrite thin film

In general, sputtering is used for spinel ferrite thin film deposition. However, it requires high temperature (>600°C) and high vacuum, thus the substrate is limited for heat-resistive one. Our group developed spin-spray method for spinel ferrite thin film deposition. Spin-spray method can directly deposit ferrite film on the substrate at low temperature.

Figure on the right shows cross-sectional SEM image of spin-sprayed ferrite film. It is as uniform and dense as sputtered ferrite film, and its deposition rate is faster than that of sputtered ferrite film.

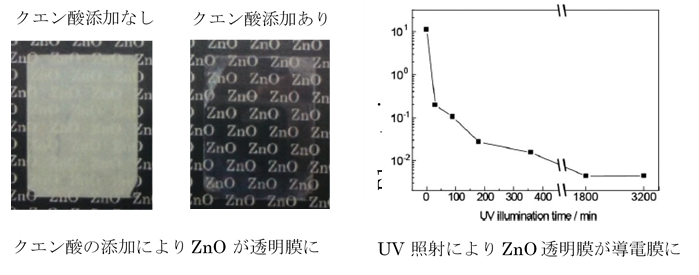

・ Zinc oxide transparent conductive film

Transparent conductive film (TCF) is used in display, OLED, touch panel and etc. At present, indium doped tin oxide (ITO) is widely used as TCF. However, In is rare-metal and the price is not stable. Hence, recently ZnO is attracting a lot of attentions as an alternative material for ITO. ZnO TCF is mainly fabricated by dry process like sputtering, and there are few reports on solution process. It is difficult to deposit a dense and conductive film by solution process. Our group have successfully fabricated ZnO TCF using spin-spray method as low temperature as 90°C, by combining the addition of citric ion and UV irradiation.

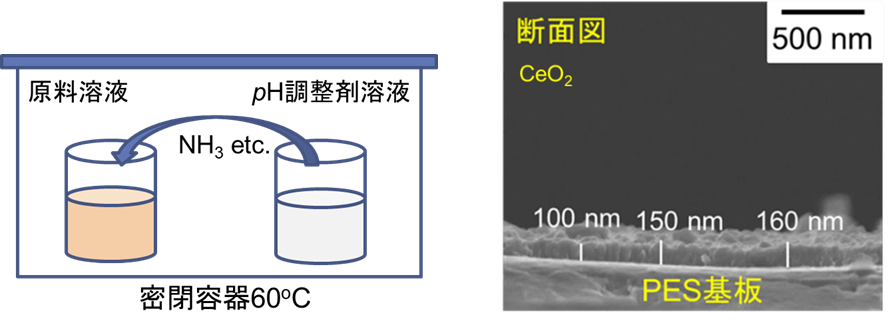

Development of novel solution process

・Basic Gas assisted Liquid Phase Deposition (BG-LPD)

Metal-oxide thin films are used in various applications, such as SOFC, TFT, solar cell and etc. Therefore, development of new devises and thin film deposition techniques should be advanced at the same time. Since general thin film deposition techniques usually require highly environmentally loading process, novel and less environmentally loading process need to be developed. Our group are focusing on Basic Gas assisted Liquid Phase Deposition (BG-LPD). Source solution and pH buffer solution are kept standing in closed box, and the box heated around 60℃. The advantage of the process is that vaporized basic gas can gradually dissolve into source solution. In this system, the reaction occurs slower and milder than just adding basic solution directly into the source solution. By modifying pH buffer and solvent, various kind of metal-oxide film can be deposited. Our group have already succeeded to fabricate CeO2 thin film on Ni and PES substrates. Now we focus on ZnO and another ion doped metal-oxide films deposition in this process.

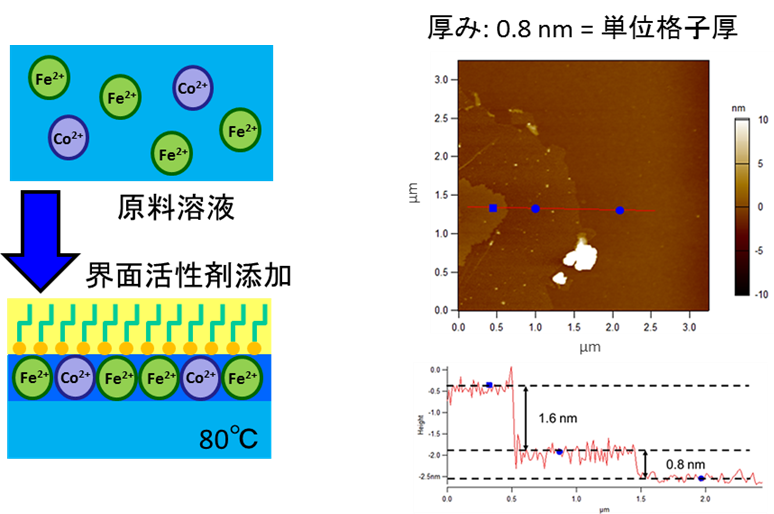

・ Fabrication of functional metal-oxide nanosheet using surfactant-oriented interface

Nanosheet is highly anisotropic 2D material, whose thickness/width are around 1-nm/several-μm order. Unlike the bulk material, the nanosheet shows interesting characteristics owing to its nano-order thickness and high anisotropy. In general, it is obtained by peeling off a single layer from the multi-layered material. However, in this peeling process, starting material has to be layered material. Our group trying to fabricate an oxide nanosheet by bottom-up process: Surfactants are aligned on gas-liquid interface and act as a template for nanosheet fabrication. The process can fabricate oxide nanosheets below 100℃. We already have fabricated cobalt-incorporated ferrite (CoxFe3-xO4) single-lattice-thick nanosheet by using aligned surfactants as a template. Further development of various kind of oxide nanosheets fabrication is in progress.

・ Fabrication of functional zinc oxide nanostructures

ZnO is one of the functional ceramics which can be made by solution process. ZnO is an abundant and inexpensive material and therefore a lot of research on ZnO for optoelectronic application are now in progress. Our group have already fabricated nano-micron sized ZnO which have various morphology and characteristics by using hydrothermal and solvothermal methods.

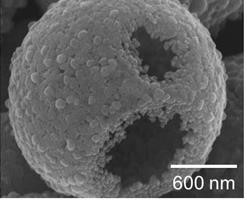

ZnO hollow particle has many advantages such as high specific surface area, low density and low refractive index, therefore it is expected to be applied for photocatalyst and DSSC. However, it is necessary to use polystyrene sphere as a template for fabricating a hollow sphere particle. Our group succeeded to directly fabricate ZnO hollow particle by solvothermal method without using any template.

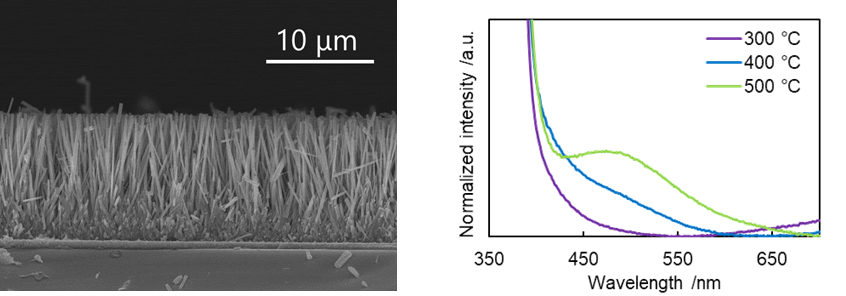

Nitrogen doping can reduce the bandgap of ZnO, thus nitrogen doped ZnO is expected to be applied for visible light photocatalyst. However, nitrogen doping usually requires the energy-consuming post-doping method, such as ion implantation and heat treatment in ammonia. Our group successfully fabricated nitrogen doped ZnO nanorod arrays by hydrothermal synthesis using a zinc-ammine-hydroxo complex solution, followed by just annealing under ambient conditions. NH3-ligands in the precursor were incorporated in ZnO during crystal growth and were then ruptured during annealing.

Solution process for biomaterials

・ Nobel implant material by surface modification of metallic glass

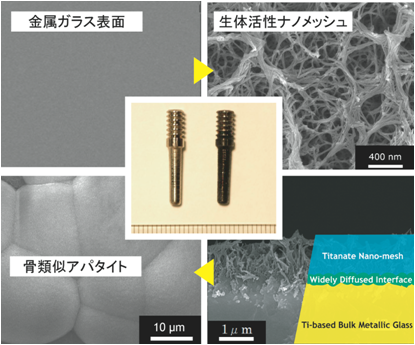

In general, metallic materials are used as implant material. However, when the metallic materials are implanted directly into our bodies, rejection reaction will be occurred. Thus, it is necessary to modify the surface of the metallic material and make it bioactive.

Our group focus on metallic glass for new implant material because it has high mechanical strength. As well as another metallic material, metallic glass is also bioinactive and do not make a bonding with bone. We use hydrothermal-electrochemical method to make a bioactive layer on it and we have succeeded to induce hydroxyapatite. This is the first report to make the metallic glass bioactive.

・ Biosensor by oxide electrodes

A biosensor is an analytical device, used for the detection of a biological analyte, such as DNA, lipid, glucose. Enzyme, receptors and antibodies are used as a detecting element, and most of them are biomaterials, which are responsible for advanced in-vivo molecular recognition mechanisms. In addition, electrodes, semiconductor elements, thermistors, photon counters are used for transducers that convert the reaction between specific molecules and biomaterials into electrical signals.

Our group are investigating on quantitative biosensor for detecting cTnT (Cardiac troponin T) in blood using an inexpensive FTO electrode as a transducer. Additionally, by making it compact, it is expected to reduce the reaction time and the amount of collected blood.

・ Controlling the corrosion resistance of the magnesium alloy

Some medical implants, such as fracture fixation materials, stents and sutures, become unnecessary after recovery. If it is made by a material that is absorbed and disappeared in our bodies, it can greatly reduce the physical and financial burden of the patients. Therefore, biodegradable polymers and bioabsorbable ceramics are currently used in relatively low loading sites, but this is only a small part, and bioabsorbable metals with excellent mechanical strength, toughness and rigidity are necessary to be developed. Magnesium alloys have good bioabsorbability and little harm to living body after absorption. However, magnesium alloy tends to be absorbed before recovery because its corrosion rate is too fast. Therefore, it is required to control the corrosion resistance of the magnesium alloy. Our group succeeded to enhance corrosion resistance of the magnesium alloy by hydrothermal and anodizing treatment in Na3PO4 and NaOH solution. It is expected that it can be applied to various parts of the body by clarifying the mechanism of improvement of corrosion resistance and controlling the corrosion resistance.